Thermal Elements

There are different methods to tell the temperature in everyday life. From mercury to alcohol-based thermometers, liquid crystal foils or electric devices with specific temperature sensors.

Operating temperature ends with most devices at around 400 °C. And there is also the challenge of measuring the temperature at one specific point.

A thermal element is a combination of two dissimilar metals or metal alloys. Those get welded or soldered at their contact point where an electro motoric force forms as a result. This force is proportional to the occurring temperature.

Conventional thermal elements prove to have two main downsides: The expensive manufacturing process and the indirect placement on the surface.

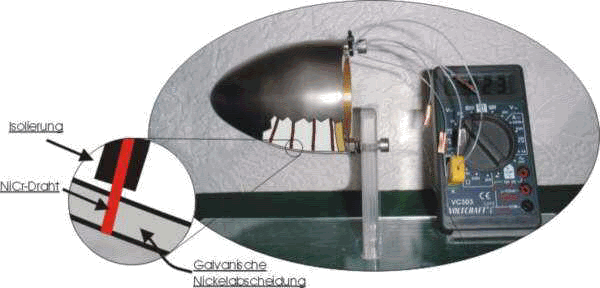

Galvanic thermal elements are a much more elegant method to those problems. Thin NiCr wires were placed on a aluminum base shape. After preprocessing, the aluminum body got plated with 2 mm of nickel while the wire ends were incorporated seamlessly into the galvanic layer.

The aluminum body got etched out leaving behind a conical nickel skin with 25 NiCr wires plated into it that make up just as many thermal elements and allowed an optimal measurement of temperature distribution.

This method allows us to install several measuring points in a very small area with only one derivation. A combination of constantan and copper is also possible.

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.