Galvanized Heating Conductors

Electrical heating conductors are being used as trace heating units for many applications. Connecting the heating conductor as closely as possible with the main body often poses a problem. Usually, the heating conductor gets firmly placed unto the main body on top of, or, if possible, into grooves.

This, however, causes only partial contact and therefore bad thermal conductivity. It can be improved by soldering, but the heating conductor’s stainless-steel case tends to wet incompletely and can suffer from overheating.

Electroplating can help with all those disadvantages. A flawless connection between electro-deposited copper, heating conductor and main body are the main conditions here. All parts must go through different preprocessing according to their base material.

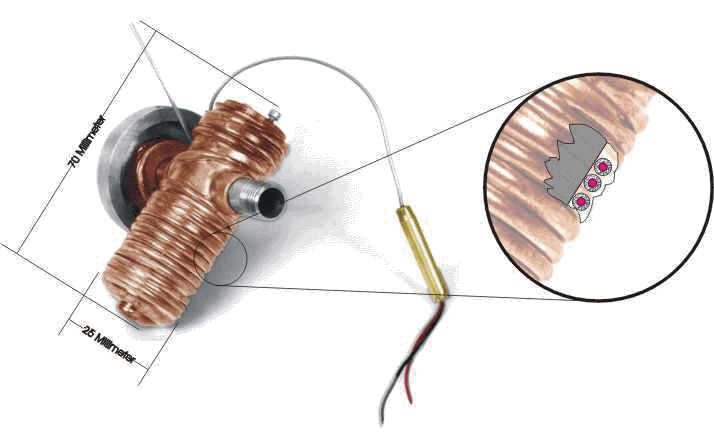

We’ll exemplify the advantages of electroplating on a charge exchange channel for negative Helium ions, a so-called Lithium Oven.

This Lithium Oven (see illustration above) must be heated up to 600°C as quickly as possible.

The American producer coiled the heating conductors around the copper cylinder and fixed them with clamping sleeves. Due to the bad contact between main body and heating conductor the research operations were interrupted frequently, which not only left the personnel with a constant feeling of insecurity but also the loss of the heating conductor itself.

The end-user, the institute of solid-state research Jülich, proposed to have the heating conductors embedded in galvanized copper. This resulted in a heating time that was four times as quick as before and a service duration that was ten times higher, too.

Advantages of Electroplating

Almost any metallic base body can be fitted with a heating conductor and galvanized afterwards. Plastic parts can be coated with a metallic layer and get heated that way as well. The plating happens at room temperature, therefore, warping and changes in firmness don’t happen.

Partial plating is also possible; parts that are not supposed to get another coat, get covered and spared.

An even more optimal temperature distribution can be achieved by placing the heating conductors further apart, making use of transverse conductivity.

Thermal conductivity of GT-copper: 350-400 W/m x K

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.