HE 11 Waveguides

For the transmission of the power of millimeter waves into the megawatt range it needs oversized waveguides to avoid arcing. To reduce transmission loss (caused by wall currents) grooved waveguides are being used (wall tension instead of wall currents).

Since the fundamental wave (HE 11) is only slightly damped an additional dampening layer is added to reduce further arcing of higher modes.

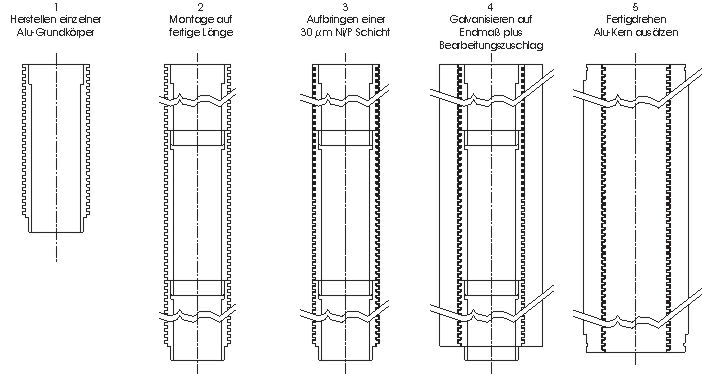

In a collaborative effort between the institute of plasma physics in Stuttgart and Galvano-T a multilayered grooved waveguide was developed that is also inexpensive to manufacture.

To create the highly precise inner contour an aluminum pipe was turned to mirror the grooves of the waveguide (negative shape). Since the galvanic layer is an exact negative of the base shape the inner contour of the waveguide can be created precisely.

The false mode dampening Ni/P layer (at least 30µm thick) is fortified with a 2-6 mm thick copper layer.

To get an offset free connection to other waveguides fits were turned into their ends.

After the aluminum main body is etched out the waveguide gets treated with a special cleaning procedure and is ready to use.

We are currently manufacturing components with the following dimensions:

Length: 2000 mm (2800 mm are possible with our current ressources)

Inner diameter: 23-90 mm

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.