Thin-walled Structures

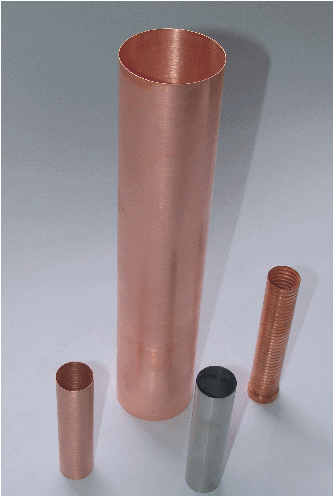

Thin-walled components of 0,5 mm or less are challenging to process in mechanical manufacturing. Electroplating, however, provides a simple procedure that creates thin-walled structures without hassle.

Since the core only gets processed from the outside, complex inner structures (like groves in waveguides) are perfectly possible.

Depending on specifications different materials may be used for the inner core, which can either be demolded, etched away, or dissolved by other chemical processes.

Copper, nickel, or a combination of both are usually used for this procedure. Potential applications for thin-walled structures are flexible waveguides, heat conductors or thin-walled sleeves for electrical or geological purposes.

Advantages of galvano-t

Competent expert consulting

Call +49 (0) 2292-6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.