Transition from Elliptical to Rectangular in Waveguides

Waveguide transitions are used to create a changeover between a flexible, elliptical waveguide to a rectangular aerial connector.

Function and performance of such components are dictated by their complicated inner contour.

It’s very difficult, sometimes even impossible, to craft components like that mechanically. Therefore, compromises must be made that reduce performance.

Electro-forming, however, offers an elegant and inexpensive solution.

Basically, the core of this process is based around creating an exact negative shape of the electrically conductive base body. Perspex, stainless steel, or invar serve as core material depending on size and quantity of the parts.

If components can’t be demolded, wax or aluminum forms are used instead.

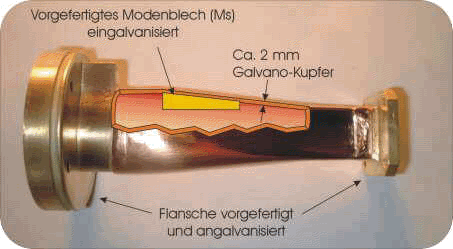

This specific transition from E75/15 – PBR 120 is a fitting that serves in transitional radio. Its job is transitioning the overmodded operating mode inside the elliptical waveguide to base mode of the antenna line. Depending on the mode sheet that got galvanized into the component the range is between 12,75-13,25 or 13,75-14,5 Ghz.

In this case copper gets deposited on a multi-piece stainless steel core. After assembling flanges and tuning plates unto the core the adhesive surfaces get activated and the exposed to several days of electro-plating. The separation of core and components is simply realized by pulling out the core.

Benefits:

• No thermal stress and, therefore, no reduction in firmness or warping

• Position of tuning elements and flanges always stay the same

• The inner contour the waveguide is exactly like the surface quality of the core

The high frequency development of this product has been conducted by the RFS kabelmetal Hannover.

Advantages of galvano-t

Competent expert consulting

Call +49 2292 6682 (Mon-Thu 8am-3pm, Fri 7.30am-12.30pm) for a free consultation with one of our experts on all kinds of technical issues, such as choosing the best material, options for implementing custom designs, etc.

ISO 9001:2015

Since 2018 we are ISO 9001:2015 certified. Thereby we meet a high standard of quality management systems

30 years of good services

We operate as a manageable, medium-sized company and deliberately keep the hierarchy flat. This philosophy has served us and our customers well for over 30 years.

Request expert advice now

Mon-Thu 8am-15pm / Fri 7.30am-12.30pm

Products

500 Mhz Cavity, Beschleunigungsgitter (NBI), Eingalvanisierte Heizleiter, Faraday Schild, Schabewärmetauscher, Thermoelemente und mehr....

Material

We are specialized in producing components by electroforming. Mainly we process copper and nickel

Procedure

Thin-walled structures, Electroforming on cores, Solderable coatings, Repair of continuous casting molds, Adhesive coating of stainless steels.

Research

We have been involved in various research projects, especially in the fields of nuclear fusion and space research, for 30 years.